Currently out of stock. Please contact us for more information.

Product Details

| Quality | Rebuilt in Japan using a genuine core |

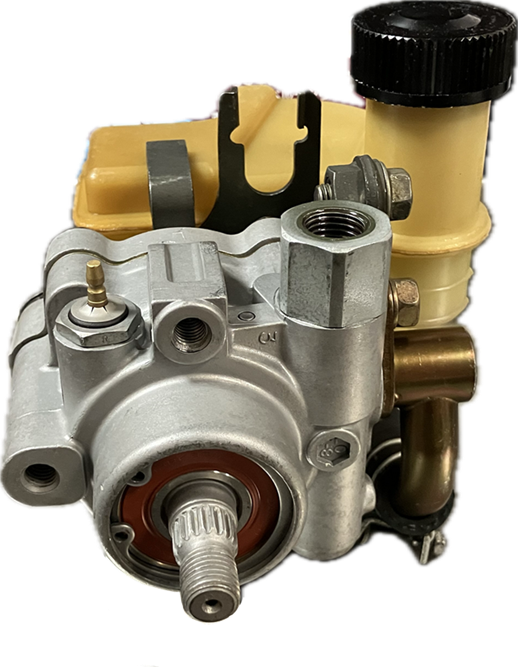

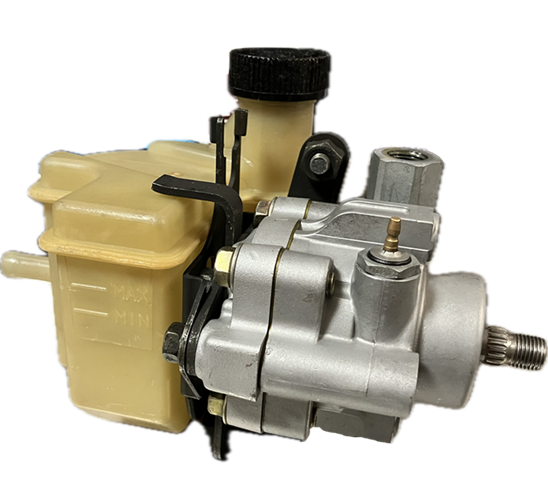

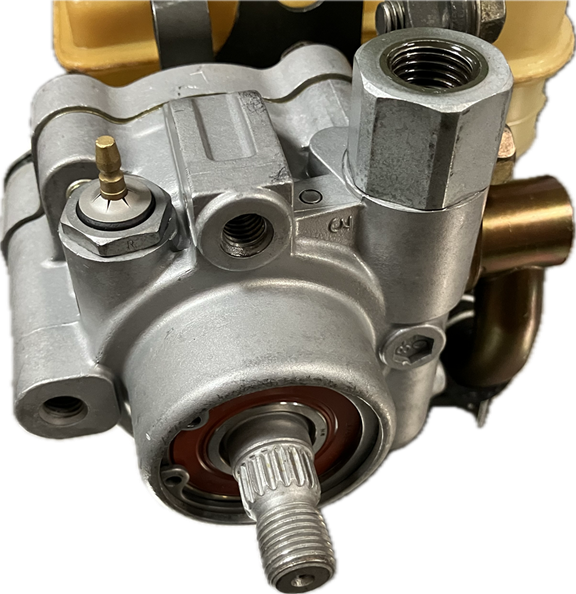

| Product Contents | – Power Steering Pump Assembly – Reservoir Tank – Gaskets for High-Pressure Hose Connection |

| MAZDA Savanna RX-7 | Model: FD3S |

| Years | 1993-2002 |

| Compatible Genuine Part Numbers | FD01-32-600C FD01-32-600D |

Product Details

| Quality | Rebuilt in Japan using a genuine core |

| Product Contents | – Power Steering Pump Assembly – Reservoir Tank – Gaskets for High-Pressure Hose Connection |

| MAZDA RX-7 | Model: FD3S |

| Years | 1994-1995 |

| Compatible Genuine Part Numbers | FD15-32-600A FD15-32-600B |

The images on this page are of actual rebuilt parts supplied by Auto Parts Box Japan.

The parts supplied by Auto Parts Box Japan are products that have undergone strict quality control by Japanese companies and possess the following features:

- Reliability – Rebuilt in Japan Using Genuine/OEM Cores.

- High Quality – Rigorous inspections and meticulous quality control.

- Durability – Providing consistent performance and peace of mind.

- Cost-Effective – Providing assured quality at a lower price compared to purchasing new parts, helping you save on your budget.

How to Check Compatibility

If you do not know the part number, please provide your vehicle’s chassis number, and we will help verify the compatible parts for your car.

Regarding Auto Parts

For more details on the rebuilt parts supplied by Auto Parts Box Japan, please see the following pages:

Types of Auto Parts

Rebuilt Parts

Contact Us

Feel free to contact us with any questions or service requests.

Prices on our website are slightly lower than on eBay, as there are no additional marketplace fees.

You’re welcome to choose whichever option is more convenient — the product and quality remain the same.

Power Steering Pump: Basic Functions and Common Problems

A detailed explanation of the power steering pump’s role, structure, and common signs of malfunction is available at the link below.

Please feel free to take a look if you’re interested.

Common Power Steering Pump Problems

- Fluid Leaks

- Unusual Noise or Fluid Foaming (Cavitation)

- Heavy Steering Feel

Power Steering Pump Overhaul – Recommended Hose Replacement

On older vehicles, when overhauling the power steering pump, we recommend replacing the hoses at the same time.

Hoses are prone to age-related wear such as hardening and cracking, and the clamping force of the clamps may also deteriorate over time.

Even if there were no leaks before, it is not uncommon for power steering fluid to start seeping from the hoses after the final inspection or test run. This often occurs because the process of removing and reinstalling the hoses can put additional stress on aged components, leading to seepage after reassembly.

Note: For some models, hoses may already be discontinued. Please feel free to contact us for availability.

Power Steering Pump FAQ

-

What does a power steering pump do?

-

The power steering pump generates hydraulic pressure to assist the driver in turning the steering wheel more easily. It supplies pressurized fluid to the power steering rack, reducing steering effort—especially at low speeds.

-

What are the symptoms of a failing power steering pump?

-

Common signs include:

- Whining or groaning noises when turning the steering wheel

- Leaking power steering fluid

- Heavier-than-usual steering

- Fluid foaming in the reservoir

- Jerky or inconsistent steering response

-

What causes a power steering pump to fail?

-

Possible causes include:

- Worn internal components (vanes, bearings, seals)

- Contaminated or low fluid

- Faulty flow control valve

- Loose or worn power steering belt

- Problems with the steering rack

-

Should I replace my alternator with a used, rebuilt, or brand-new unit?

-

Each option has its pros and cons:

- Used Power Steering Pump:

Affordable, but condition and lifespan are uncertain. Internal wear may not be visible, and there’s no guarantee how long it will last. Best suited for short-term use or temporary fixes. - Rebuilt Power Steering Pump:

A cost-effective and reliable option when rebuilt by professionals using genuine components. It’s fully inspected, worn parts are replaced, and performance is restored. Ideal for those seeking quality and savings. - Brand-New Power Steering Pump:

Offers maximum reliability and warranty coverage, but typically comes at a higher price. Best for those prioritizing long-term peace of mind and minimal downtime.

- Used Power Steering Pump:

The Stress Drifting Puts on the Power Steering Pump

- Frequent and Rapid Steering Input

- Frequent “lock-to-lock” movements:

During drifting, the driver repeatedly and rapidly turns the steering wheel from full left to full right—something rarely done in normal driving.

This causes the power steering pump to operate near its maximum pressure almost constantly, putting a significant strain on the system. - Quick countersteering:

Countersteering (turning the wheel in the opposite direction of the vehicle’s slide) must be performed quickly and precisely.

These sudden and aggressive steering inputs create sharp, momentary loads on both the power steering pump and the rack.

- Frequent “lock-to-lock” movements:

- High Tire Friction and Steering Kickback

- Lateral tire slip:

During a drift, the tires slide sideways across the road surface, generating intense friction.

This friction translates into strong kickback forces that are fed back into the steering system. - Increased resistance:

In normal driving, most friction occurs in the direction of travel. In drifting, however, the tires are angled and sliding sideways, which increases resistance against the steering axis.

The power steering system must overcome this resistance, requiring higher hydraulic pressure.

- Lateral tire slip:

- Fluid Overheating and Degradation

- Pump overheating:

Constant high-output operation and increased resistance cause the power steering fluid temperature to rise rapidly. - Fluid foaming (cavitation):

As fluid temperature increases, viscosity decreases. Under intense pump operation, this can cause cavitation—where air bubbles form in the fluid.

Since air is compressible, this leads to unstable hydraulic pressure and, at times, temporary loss of steering assist. - Fluid overflow:

Foaming increases the volume of the fluid, which may cause it to overflow from the reservoir tank.

If the fluid contacts hot engine components, it could be dangerous.

In addition, a loss of fluid can lead to pump starvation or even pump failure due to overheating.

- Pump overheating:

Rotary Engines and the “Onigiri” Rotor

Unlike regular engines where pistons move up and down inside cylinders to generate power, a rotary engine doesn’t use pistons at all.

The Moving “Onigiri” That Powers the Engine!

At the heart of a rotary engine is a triangular-shaped part that looks surprisingly like a Japanese rice ball, or onigiri. This part is called the rotor.

As this onigiri-shaped rotor spins around inside a specially shaped housing, it burns fuel and generates power.

Why is it Called an “Onigiri”?

The nickname comes from its rounded triangular shape, which resembles onigiri — a traditional Japanese rice ball, usually hand-shaped into a triangle and wrapped in seaweed. It’s a beloved snack in Japan, and car fans affectionately use the term to describe the rotor’s familiar shape.

Thanks to this unique design, rotary engines are incredibly compact yet capable of producing impressive power.